Shopping Cart

0 item(s) - 0.00€- Allis-Chalmers (28)

- Atlas (103)

- Case International (46)

- Claas (3)

- David Brown (17)

- Deutz (168)

- Deutz Diesel Engine (23)

- Fendt (44)

- Fiat (92)

- Ford (61)

- Holder (22)

- John Deere (135)

- Komatsu (117)

- Kubota (114)

- Lanz (3)

- MAN (2)

- Massey Ferguson (42)

- Mc Cormick International (47)

- New Holland (60)

- Renault (1)

- Same (3)

- Steyr (6)

- Terex (6)

- Valtra (4)

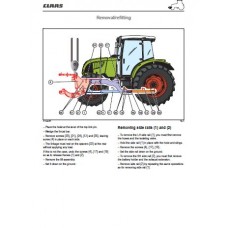

Claas Ares 547 - 557 - 567 - 577 - 617 - 657 - 697 Workshop Manual

Add to Compare

Workshop Manual Claas Ares 507 Series / Claas Ares 607 Series

Claas Ares 547

Claas Ares 557

Claas Ares 567

Claas Ares 577

Claas Ares 617

Claas Ares 657

Claas Ares 697

1599 pages

Language: English

You will receive the downloadlink of the digital manual (pdf) in your email account after your payment

Contents:

Injection Sheet Checking Procedure

Checking Procedure

Measurement and Checking Points

Appendix

DE 10 Injection

Description

Description and Operation

Additional Technical Details

Tightening Torques

Filter Element

Injector Pump

Injector

Electronic Control

Manifold Air Temperature Sensor

Engine Coolant Temperature Sensor

Fuel Temperature Sensor

Crankshaft Position Sensor

Pump Control Solenoid

Accelerator Detector

Engine Tier II

General Desription

Technology of Non-Moving Parts

Technology of Moving Parts

Lubrication

Cooling

Air

Tightening Torques

Dimensional Specifications

Check

Removal / Refitting

Diagnostic Sheets

Gearbox

Mechanical Part

General Description

" Hexashift " Module

Reverter Module under Torque

Robot-Driven Ranges Module

Crawler Ranges Modules

Characteristics GBA 25

Dismantling Procedure

Main Adjustments

Torque Settings and Sealants

" Hexashift " Module

Reverter Module under Torque

Robot-Driven Ranges Module

Slow Range

Extra Slow Range

Hydraulic Part

Low Pressure Circuit 20 Bar

Low Pressure Lubrication Circuit

Characteristics of Low Pressure Circuits

Open Center 60 L/MIN

" Load Sensing " 100 L/MIN

" Load Sensing " 110 L/MIN

Control Circuit Tightening Torques

Solenoid Valve Measurement and Checking Points

Control Unit GBA 25 Measuring and Checking Points

GBA 25 " Hydraulic Inspection Results" Sheet

60 L/MIN Open Centre Measurement and Checking Points

60 L/MIN Open Centre "Inspection Results" Sheet

" Load Sensing " 100 L/MIN Measuring and Checking Points

" Load Sensing " 100 L/MIN "Inspection Results" Sheet

" Load Sensing " 110 L/MIN Measuring and Checking Points

" Load Sensing " 110 L/MIN "Inspection Results" Sheet

Electronic Components

Electronic Transmission Control

Gearbox Electronic Control

Component Layout

Electrical Tests

Adjustments and Calibration

" Speed and Safety " Measurement and Checking Points

" Supply " Measurement and Checking Points

" Hexashift " Measurement and Checking Points

" Robot-Driven Range " Measurement and Checking Points

" Shuttle Reverser " Measurement and Checking Points

" Mode Management " Measurement and Checking Points

" Overdrive " Measurement and Checking Points

" Slow " Measurement and Checking Points

" Display " Measuring and Checking Points

Rear Axle

Mechanical Part

Presentation of the Rear Axle

Tightening Torques and Principal Adjustments

" HD " Axle Tube

" SHD " Axle Tube

Crown Wheel and Pinion and Differential

Rear Power Take Off Clutch

Rear Power Take-Off Upper Shaft

Rear Power Take-Off Lower Shaft

Power Take-Off Sensor and Control

Proportional PTO

Transmission Service Brake 40 KM/H

Transmission Service Brake 50 KM/H

Transmission Hand Brake 40 KM/H

Transmission Hand Brake 50 KM/H

Hydraulic Part

Low Pressure Circuit 20 Bar

Braking 40 KM/H

Braking 50 KM/H

Lubrication System

Open Center 60 L/MIN

" Load Sensing " 100 L/MIN

" Load Sensing " 110 L/MIN

Torque Settings

60 L/MIN Open Centre Measurement And Checking Points

60 L/MIN Open Centre " Inspection Results " Sheet

" Load Sensing " 100 L/MIN Measuring And Checking Points

" Load Sensing " 100 L/MIN " Inspection Results " Sheet

" Load Sensing " 110 L/MIN Measuring And Checking Points

" Load Sensing " 110 L/MIN " Inspection Results " Sheet

Transmission Braking Circuit ( 40 KM/H Version )

Transmission Braking Circuit ( 50 KM/H Version )

Electronic Components

Electronic Rear Axle Control

Component Layout

Electrical Tests

" Low Pressure Hydraulic System " Measurement and Checking Points

" Engine Speed " Measurement and Checking Points

" Supply " Measurement and Checking Points

" 4-Wheel Drive Unit " Measurement and Checking Points

" Differential Lock " Measurement and Checking Points

" Power Take-Off " Measurement and Checking Points

" Braking " Measurement and Checking Points

Rigid Front Axle

Mechanical Part

General

Main Torques

Wheel Alignment

Preliminary Operations

Steering Cylinder

Epicyclic Reduction Gear and Wheel Hub

Wheel Swivel Pin

Bevel Gear and Differential

4 Wheel Drive Unit

Hydraulic Part

Operation

Measurement and Checking Points

" Inspection Results " Sheet

Electronic Part

Front Axle

4 Wheel Drive Unit

Proactiv Front Axle

Mechanical Part

General

Main Torques

Wheel Alignment

Preliminary Operations

Steering Cylinder

Epicyclic Reduction Gear and Wheel Hub

Wheel Pivot and Upper Arm

Suspension Cylinder and Lower Arm

Universal Joint Shaft

Bevel Gear and Differential

4 Wheel Drive Unit

Hydraulic Part

Description

Operation

Components of the Unit

Hydraulic Systems

Measurement and Checking Points

" Inspection Results " Sheet

Hydraulic Block

Electronic Part

Description

Diagnostics

Adjustments

Measurement and Checking Points

Common Elements

Presentation of Linkage

Linkage Operation

"SNR" Brake Valve Operation

"Cuna" Brake Valve Operation

Steering Unit

Auxiliary Spool Valve

Linkage

Braking Valve

Open Center 60 L/Min

Description

Component Layout

RH Cover

LH Cover

Hydraulic Measurement and Checking Points

Measurement and Checking Points

"Hydraulic Inspection Results" Sheet

"Load Sensing" 100 L/MIN

Description

Component Layout

RH Cover

LH Cover

Circuit Selector

Hydraulic Measurement and Checking Points

"Hydraulic Inspection Results" Sheet

"Load Sensing" 110 L/MIN

Description

Operation

Component Layout

Priority Unit

RH Cover

LH Cover

Booster Pump

Hydraulic Measurement and Checking Points

"Hydraulic Inspection Results" Sheet

Electrical Services

Item List - Wiring and General Lists

Schematic Diagrams According to Functions

Harness and Connector Paths

Instrument Panel

Description

Characteristics

Removal / Refitting

Adjustments

TCE 15 T Electronic Lift

Description

Checks and Adjustments

Infotrac and Iso Socket

Presentation of the "Infotrac"

Presentation of the Iso Socket

Removal / Refitting and Electrical Checks

Adjustments

Electropilot

Description

Spool Valves

Electrohydraulic Spool Valve ( "DEH" )

Additional Technical Details

Removal / Refitting

Check

Measurement and Checking Points

"Inspection Results" Sheet

WIN MÉTADIAG Manual

WIN MÉTADIAG Version Update

Connecting with MÉTADIAG

Engine Application

Service Brake Cut-Out Relay Solenoid Valve ( Centre Open at Rest )

Transmission Display Application

Rear Lift Application

Dashboard Application

Electropilot Application

Climate Control

Cab Lifting and Glass Bonding

Description

Removing the Cab

Refitting the Cab

Removal / Refitting of Glazing

Manual Heating / Air Conditioning

Characteristics

General Description

Positioning of Components

Description and Operation

Safety Instructions

Gas Charging and Discharging

Removal / Refitting

Diagnostics

Regulated Heating and A/C

Climate Control

Front Lift Linkage and Attachment Points

Characteristics

Torque Settings

Removal / Refitting

Measurement and Checking Points

"Inspection Results" Sheet

Attachment Points

Front Power Take-Off

Front Power Take-Off Unit

Electrical Tests

Measurements and Checking Points

"Inspection Results" Sheet

Pneumatic Brake

General Description

Presentation of the Different Systems

Technological Concepts

Description

Operating Principle

Torque Settings and Sealants

Measurements and Checking Points

Tools