Shopping Cart

0 item(s) - 0.00€- Allis-Chalmers (28)

- Atlas (103)

- Case International (46)

- Claas (3)

- David Brown (17)

- Deutz (168)

- Deutz Diesel Engine (23)

- Fendt (44)

- Fiat (92)

- Ford (61)

- Holder (22)

- John Deere (135)

- Komatsu (117)

- Kubota (114)

- Lanz (3)

- MAN (2)

- Massey Ferguson (42)

- Mc Cormick International (47)

- New Holland (60)

- Renault (1)

- Same (3)

- Steyr (6)

- Terex (6)

- Valtra (4)

Same Solaris 35 - Solaris 45 - Solaris 55 Operators Manual

Add to Compare

Operators and Maintenance Manual

Same Solaris 35

Same Solaris 45

Same Solaris 55

288 pages

Language: English

You will receive the downloadlink of the digital manual (pdf) in your email account after your payment

Contents:

Preface

Table of contents

Important

Safety

Introduction to Safety

Safety

AWord to the Operator

Danger, Warning, Caution

Follow a Safety Programme

For Safe Operation

General safety rules

Protective Structures

Roll Over Protective Structures

Operation

Damage to the ROPS

Cab

Prepare for Safe Operation

Protect Yourself

Risks from exposure to noise

Know Your Equipment

Use all Available Protective and Safety Devices

Check the Equipment

Clean the Tractor

Protect the Environment

Servicing the Tractor

Starting

Warn Personnel before Starting

Mount and Dismount Safely

Start Safely

Follow Recommended Starting Procedures

Test the Controls

Starting Fluid

Work Safely

Making the Right Moves

Follow Safe Operating Practices

Watch out for Others

Risk of Overturning

To Avoid Side Overturns

To Avoid Rear Overturns

General Operating Hazards

Implements and Attachments

Safety - Towing

Road Transport

Rules of the Road

After Operation

Welding work on the tractor body

Safety instructions for the installation of supplementary equipment and/or electronic components

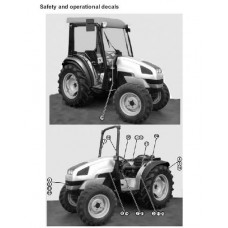

Safety and operational decals

International symbols (Part. 1)

International symbols (Part. 2)

International symbols (Part. 3)

Metric conversion

Conversion tables

Replacement parts

Tractor serial number

Engine serial number

Tractor identification plate

Original replacement parts

Use

Checking the tractor prior to starting work

Refuelling

Checking the engine oil level

Access to the driving position

Lights' switch

Instrument panel

Fuel gauge

Engine temperature gauge

Tachometer

Pilot lights'

Warning light

Front/rear differential lock button

Emergency flashers control

Hand accelerator

Ignition switch

Engine

Precautions for optimum engine performance

Starting the engine

Electronic control of engine cooling system

Engine shut down

Cold starting

Emergency starting through auxiliary battery

Turbocharging

Manual emergency stop

Adjusting the driver’s seat

BOSTROM Minibaltic XH2 seat with spring suspension

KAB P4 XH2 sprung seat

Adjusting the rearview mirrors

Control pedals

Clutch control pedal

Brake pedal

Handbrake lever

Accelerator pedal

Gearbox and P.T.O. clutch

Controls located to the right of the driver

Gearbox controls

Transmission speed selection

Front and rear differential lock

Front-wheel drive

Power take-off

Front P.T.O. (1000 rpm)

Rear - central PTO

Synchronized power take-off

Underside P.T.O. for control of implements mounted underside

Rear brakes

Load sensing - mechanical lift

Controls

Hydraulic system

Auxiliary hydraulic services control valve

Nomenclature

Types of auxiliary hydraulic service control valve

The controls

Example connection and operation of a double-acting cylinder

Connection of an implement to the auxiliary

hydraulic service couplers

Converting a control valve from double-acting to single-acting

Example of connection to a single-acting cylinder

Class “A” drawbar

Towing hitch

Class “C” towing hitch

CEE towing hitch

Three-point linkage

Adjustment of the telescopic stabilisers

Adjustment of the top link

Adjustable vertical link

Mid mount implements with lifting arms

Hydraulic front lift

Bodywork

Safety frame

Cab

GRAMMER MSG 83/8 type seat

Ventilation

Controls

Heating system

Air conditioning

Controls located in the cab roof lining

Opening front window

Opening rear window

Cab roof light

Storage compartment

Digital quartz clock

Active carbon air filter

Cable channel for passing external implement control

cables into the cab

Hazard warning triangle

Screen wash liquid reservoir

Wheels

Track adjustment

Tyre inflation pressures

Width of the front axle (without wheels)

Mechanical ratio (front wheel revolutions / rear wheel revolution)

Width of rear axle (without wheels)

Row crop tires

Running direction of tires

Adjusting steering stops

Adjustable track wheels

Permissible tyre combinations

Track width adjustment for wheels with adjustable rims

Front wheels

Rear wheels

Track width adjustment for wheels with fixed rims

Ballast

Front horizontal ballast blocks

Rear ballast

Ballasting by filling the tyres with water + antifreeze solution

Filling the tyre with water

Draining water from the tyre

Maintenance operations

Lubricants and fluids

Maintenance intervals

Maintenance and inspection schedule

Fuel storage

Refueling

Refueling at the end of the day

Engine maintenance

Raising the engine hood

Cleaning the front grille

Checking the engine oil level

Changing the engine oil

Changing the engine oil filters

Cleaning and replacement of the fuel filter

Bleeding air from the fuel system

Electro-magnetic fuel pump

Filter periodic maintenance

Filter replacement

Filter inspection and cleaning

Fuel

Air filter

Cleaning the air filter

Engine cooling system

Checking the level of coolant in the expansion tank

AKROS FREEZE liquid coolant

Changing the coolant/antifreeze mixture and flushing the

cooling system

Thermostat

Cleaning the oil cooler

Adjusting belt tension

Gearbox clutch

Rear and underside P.T.O. clutch

Maintenance of the gearbox, differential and rear reduction units

Checking the transmission oil level

Changing the oil

Maintenance of the hydrostatic power steering

Bleeding air from the hydraulic system

Checking operation of the differential lock controls

Maintenance of the front and rear brakes

Checking the braking action

Front differential lock (if installed)

Maintenance of the front wheel drive system

Front axle and hub final drives (4WD)

Front axle pivot bushes

Maintenance of hydraulic power-lift

Maintenance of the 3-point linkage

Rear 3-point linkage

Maintenance of Front P.T.O

Maintenance of front lift

Windscreen washer

Windscreen and rear screen wipers

Maintenance of the air conditioning system

Cab air filter (cleaning)

Active carbon air filter

Maintenance of the heating system

Maintenance of the air conditioning system

Checking the air conditioning system

Air conditioning system compressor

Air conditioning system

Air conditioning system recharging and maintenance valve

General cleaning of the tractor

Cleaning with detergents

Cleaning with compressed air

Electrical system

Battery

Checking the battery

Fuse box

List of electrical system components

Fuse box

Connector for connection to front wiring loom

Connector for connection to rear wiring loom

Cab electrical system wiring

Electrical diagram - cab air conditioning unit

Cab fuse box

Rear outlet socket - standard

Cab electrical system wiring

Wiring for cab air conditioning unit

Wiring for radio

Wiring for cab

Wiring for worklights

Lights

Cleaning the headlights and sidelights

Bulb replacement

Rear light assemblies

Front sidelights and direction indicators mounted on the sides of the tractor

Front and rear working lights in cab roof

Interior light

Rear work lights for tractors with platform

Headlight alignment

Horizontal adjustment

Vertical adjustment

Storage of the tractor

Operations prior to garaging the tractor for a long period

Preparing the tractor for use after a long period of storage

Technical specifications

Engine

Clutch

Power take-off

Gearbox

Gearbox ratios schematic

Performance - Ground speed in km/h (mph) @ 3000 rpm

Front driving axle

Hydrostatic steering system

Front hydraulic lift

Hydraulic diagram of lift

Hydrostatic steering system

Cab

Dimensions and weights

Unladen weight of tractor (without ballast)

Unladen weight of tractor (with ballast)

Maximum permissible loads

Maximum trailerable loads

Ballast weights

Attachment of implements to the tractor

Implement attachment points

Fault diagnosis

Engine

Gearbox

Rear power take-off

Front driving axle

Brakes

Hydraulic lift

Auxiliary hydraulic systems

Appendix

Combination of tractor and mounted implement

Determination of the total weight, the axle loads, the tyre load carrying capacity and the necessary minimum ballasting

Consideration of rear mounted implement and front/rear combinations

Front mounted implement

Note