Shopping Cart

0 item(s) - 0.00€- Allis-Chalmers (28)

- Atlas (103)

- Case International (46)

- Claas (3)

- David Brown (17)

- Deutz (168)

- Deutz Diesel Engine (23)

- Fendt (44)

- Fiat (92)

- Ford (61)

- Holder (22)

- John Deere (135)

- Komatsu (117)

- Kubota (114)

- Lanz (3)

- MAN (2)

- Massey Ferguson (42)

- Mc Cormick International (47)

- New Holland (60)

- Renault (1)

- Same (3)

- Steyr (6)

- Terex (6)

- Valtra (4)

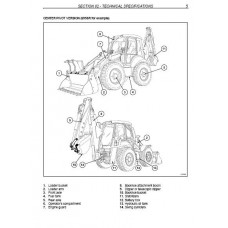

Case 580SR - 580SR+ - 590SR - 695SR Workshop Manual

Add to Compare

Workshop Manual Case Loader Backhoe

Case 580 SR

Case 580 SR+

Case 590 SR

Case 695 SR

Series 3

1068 pages

Language: English

You will receive the downloadlink of the digital manual (pdf) in your email account after your payment

Contents:

SECTION 00 - SAFETY PRECAUTIONS

SECTION 01 - MAINTENANCE

SECTION 02 - TECHNICAL SPECIFICATIONS

1. LOADER BACKHOE MODELS

2. IDENTIFICATION OF MAIN COMPONENTS

3. SPECIFICATIONS

3.1 DIESEL ENGINE

3.2 TRANSMISSION

3.3 AXLES

3.4 BRAKES

3.5 STEERING

3.6 HYDRAULIC SYSTEM

3.7 FRONT COUNTERWEIGHT

3.8 NOISE AND VIBRATION LEVELS

3.9 BUCKETS

3.10 TYRES

4. DIMENSIONS AND PERFORMANCE

4.1 LOADER ATTACHMENT DIMENSIONS AND PERFORMANCE

4.2 DIMENSIONS AND PERFORMANCE OF LOADER ATTACHMENT WITH FORKS

4.3 BACKHOE ATTACHMENT DIMENSIONS AND PERFORMANCE

5. BACKHOE ATTACHMENT LIFTING CAPACITY

6. MAXIMUM LIFTING LOADS

6.1 LOADER ATTACHMENT MAXIMUM LIFTING LOAD TABLE

6.2 BACKHOE ATTACHMENT MAXIMUM LIFTING LOAD TABLE

7. SUPPLY SUMMARY TABLE

SECTION 17 - TORQUE CONVERTERS

1. POWERSHUTTLE TORQUE CONVERTER

1.1 DESCRIPTION AND OPERATION

1.2 SPECIFICATIONS

1.3 OVERHAUL

1.4 INSPECTION

1.5 DISASSEMBLY AND ASSEMBLY

1.6 STALL TEST

1.7 FAULT FINDING

2. POWERSHIFT TORQUE CONVERTER

2.1 DESCRIPTION AND OPERATION

2.2 SPECIFICATIONS

2.3 OVERHAUL

2.4 INSPECTION

2.5 DISASSEMBLY AND ASSEMBLY

2.6 STALL TEST

2.7 FAULT FINDING

SECTION 21 - TRANSMISSION

1. POWERSHUTTLE TRANSMISSION TURNER MODEL COM-T4-2025

1.1 SPECIFICATIONS

1.2 MOUNTING SCREW TORQUE

1.3 TRANSMISSION CONTROLS

1.4 LUBRICATION

1.5 TRANSMISSION OIL FLOW AND SUPPLY

1.6 TRANSMISSION HYDRAULIC VALVES AND PRESSURE TEST POINTS

1.7 TRANSMISSION POWER FLOW

1.8 TRANSMISSION 2WD COMPONENTS

1.9 TRANSMISSION 4WD COMPONENTS

1.10 TRANSMISSION REMOVAL

1.11 DISASSEMBLY AND ASSEMBLY

1.12 FAULT FINDING

1.13 SPECIAL TOOLS

2. POWERSHIFT TRANSMISSION DANA T16000

2.1 SPECIFICATIONS

2.2 CONTROLS

2.3 LUBRICATION

2.4 PRESSURE SPECIFICATIONS AND CHECK POINTS

2.5 TRANSMISSION COOLER

2.6 HYDRAULIC DIAGRAM

2.7 OPERATION

2.8 POWER FLOWS

2.9 GEAR AND CLUTCH LAY OUT

2.10 TRANSMISSION REMOVAL AND INSTALLATION

2.11 TRANSMISSION COMPONENTS

2.12 DISASSEMBLY AND ASSEMBLY

2.13 SPECIAL TOOLS

2.14 FAULT FINDING

2.15 FAULT FINDING

SECTION 25 - FRONT AXLES

1. FRONT AXLE 2WD CARRARO

1.1 SPECIFICATIONS

1.2 DISASSEMBLY AND ASSEMBLY

1.3 FAULT FINDING

2. FRONT AXLE 4WD CARRARO

2.1 SPECIFICATIONS

2.2 DISASSEMBLY AND ASSEMBLY

2.3 FAULT FINDING

3. FRONT AXLE 4WS CARRARO

3.1 SPECIFICATIONS

3.2 DISASSEMBLY AND ASSEMBLY

3.3 FAULT FINDING

4. SPECIAL TOOLS

SECTION 27 - REAR AXLE

1. REAR AXLE 2WS

1.1 DESCRIPTION AND OPERATION

1.2 SPECIFICATIONS

1.3 DISASSEMBLY AND ASSEMBLY

1.4 FAULT FINDING

2. REAR AXLE 4WS CARRARO

2.1 SPECIFICATIONS

2.2 DISASSEMBLY AND ASSEMBLY

2.3 FAULT FINDING

3. SPECIAL TOOLS

SECTION 33 - BRAKES SYSTEM

1. SPECIFICATIONS

2. PARKING BRAKE

2.1 PARKING BRAKE ADJUSTMENT

3. BRAKE CYLINDERS

4. OIL BRAKE TANK

5. BLEEDING PROCEDURE

SECTION 35 - HYDRAULIC SYSTEM

1. HYDRAULIC DIAGRAMS

1.1 HYDRAULIC DIAGRAM - 2WS SIDESHIFT MECHANICAL MODELS

1.2 HYDRAULIC DIAGRAM - 2WS SIDESHIFT PILOT MODELS

1.3 HYDRAULIC DIAGRAM - 4WS SIDESHIFT MECHANICAL MODELS

1.4 HYDRAULIC DIAGRAM - 4WS SIDESHIFT PILOT MODELS

1.5 HYDRAULIC DIAGRAM - 4WS CENTER PIVOT PILOT MODELS

2. HYDRAULIC PUMP

2.1 DESCRIPTION AND OPERATION

2.2 SPECIFICATIONS

2.3 LOAD SENSING VALVE

2.4 REMOVAL

2.5 COMPONENTS

2.6 DISASSEMBLY AND ASSEMBLY

3. CONTROL VALVES

3.1 CONTROL VALVES REXROTH (MECHANICAL MODELS)

3.2 REXROTH CONTROL VALVES (PILOT MODELS)

3.3 SOLENOID VALVE FOR PILOTING THE BACKHOE CONTROL VALVE (WITH HYDRAULIC CONTROL)

3.4 RELIEF VALVES

3.5 ACCUMULATOR GLIDE RIDE PARKER

4. HYDRAULIC SWING SYSTEM

4.1 DESCRIPTION AND OPERATION

4.2 HYDRAULIC OIL FLOW

5. HYDRAULIC CYLINDERS

5.1 LOADER ATTACHMENT BOOM CYLINDER

5.2 LOADER BUCKET CYLINDER

5.3 4X1 LOADER BUCKET CYLINDER

5.4 BACKHOE BOOM CYLINDER

5.5 BACKHOE ATTACHMENT DIPPER CYLINDER

5.6 BACKHOE BUCKET CYLINDER

5.7 TELESCOPIC CYLINDER

5.8 4WS STABILIZER CYLINDER - CENTER PIVOT

5.9 STABILIZER CYLINDER - SIDESHIFT

5.10 SWING CYLINDER

5.11 BACKHOE ATTACHMENT SIDESHIFT CYLINDER - SIDESHIFT

5.12 SPECIAL TOOLS

6. HYDRAULIC CONTROL LEVERS

6.1 SPECIFICATIONS

6.2 DESCRIPTION AND OPERATION

6.3 DISASSEMBLY AND ASSEMBLY

6.4 CONTROL LEVER VALVE

7. FAULT FINDING

7.1 PRELIMINARY CHECKS

7.2 FAULT FINDING

SECTION 39 - CHASSIS

1. DESCRIPTION AND OPERATION

2. REMOVAL AND INSTALLATION COMPONENTS

2.1 COMPONENTS WITHIN THE CHASSIS

2.2 COMPONENTS BELOW THE CHASSIS

2.3 COMPONENTS ATTACHED OUTSIDE THE CHASSIS

2.4 COMPONENTS ATTACHED ON THE CHASSIS

2.5 MOUNTING SCREW TORQUE

SECTION 41 - STEERING SYSTEM

1. STEERING SYSTEM 2WS

2. STEERING SYSTEM 4WS

3. POWER STEERING

3.1 SPECIFICATIONS

3.2 COMPONENTS

3.3 DISASSEMBLY AND ASSEMBLY

3.4 SPECIAL TOOLS

3.5 FAULT FINDING

SECTION 50 - CAB HEATING AND AIR CONDITIONING

1. SPECIFICATIONS

2. CAB HEATING

2.1 DESCRIPTION AND OPERATION

3. AIR CONDITIONING

3.1 PRINCIPALS OF AIR CONDITIONING

3.2 SAFETY PRECAUTIONS

3.3 CONTROLS AND OPERATION

3.4 FAULT FINDING AND TESTING

3.5 FLUSHING THE SYSTEM

3.6 EVACUATING THE SYSTEM

3.7 CHARGING THE SYSTEM

3.8 COMPONENTS OVERHAUL

3.9 COMPRESSOR

3.10 SPECIAL TOOLS

SECTION 55 - ELECTRICAL SYSTEM